Views: 0 Author: Site Editor Publish Time: 2025-09-22 Origin: Site

Molding processes are essential in modern manufacturing for producing precise, high-quality parts. Die casting molds are used to shape molten metals like aluminum and zinc into durable components, while injection molds typically shape plastics, rubber, and metals by injecting molten material into a mold cavity under pressure.

Choosing the right molding process is key to achieving efficiency, material compatibility, and cost-effectiveness. Both die casting and injection molding offer unique advantages, depending on the application. This article will compare these two methods, focusing on their strengths, weaknesses, and ideal use cases, helping manufacturers choose the best option based on factors like material, design complexity, production volume, and cost.

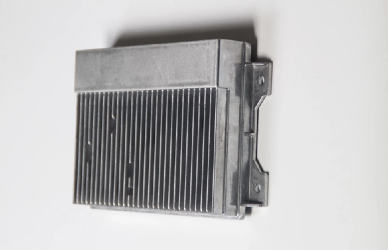

Die casting molds are used in the process where molten metal is injected under high pressure into a mold cavity. After cooling and solidifying, the metal forms precise parts. Typically made from durable materials like tool steel or aluminum, these molds can withstand high temperatures and pressures. The process includes melting the metal, injecting it, cooling, and ejecting the solid part, producing high-precision components with minimal post-processing.

Aluminum Alloys: Lightweight, strong, and corrosion-resistant, ideal for automotive and aerospace parts.

Zinc Alloys: Offer excellent surface finish and accuracy, suitable for small, detailed components.

Magnesium Alloys: The lightest structural metal, used for weight-critical parts in automotive and aerospace.

Other Alloys: Copper and lead alloys offer higher heat resistance for specialized applications.

The material choice depends on strength, weight, heat resistance, and cost.

Automotive: Die casting is used for parts like engine blocks, transmission housings, and structural components, emphasizing strength and weight reduction.

Aerospace: Parts such as turbine housings and engine components are made for strength and lightweight properties.

Industrial: Used for electrical housings, power tools, and machinery components, offering durability and performance.

Die casting molds are crucial in producing high-performance, complex, and durable parts across various industries.

Injection molds are used in injection molding, where material (typically plastics or elastomers) is melted and injected into a mold cavity under high pressure. After cooling and solidifying, the part is ejected, often requiring minimal finishing. This fast, repeatable process is ideal for mass production of complex parts.

Plastics: Thermoplastics like ABS, polypropylene, and polycarbonate are commonly used for their versatility, durability, and cost-effectiveness.

Elastomers: Rubber-like materials, such as silicone and TPEs, provide flexibility and stretchability.

Metals: Zinc and aluminum alloys are used for higher strength or heat resistance in specialized applications.

Material choice depends on strength, flexibility, and cost.

Consumer Products: Injection molds are used for items like toys, containers, and household goods.

Medical Devices: High-precision parts for syringes, valves, and connectors are made using injection molds.

Electronics: Parts for smartphones, computers, and connectors are produced for their durability and intricate designs.

Injection molding is essential for mass-producing complex, high-quality parts with high precision and efficiency.

Die Casting: Uses metals like aluminum, zinc, and magnesium alloys, offering strength and heat resistance for high-performance parts.

Injection Molding: Primarily uses plastics (ABS, polypropylene) and sometimes metals for lightweight, flexible, and cost-effective components.

Die Casting: Involves high-pressure injection of molten metal into molds, requiring high heat and longer cycle times.

Injection Molding: Uses lower temperatures to melt plastic and inject into molds, offering faster cycle times and higher production efficiency.

Die Casting: Produces strong, durable parts with complex designs, ideal for automotive and aerospace.

Injection Molding: Creates lightweight parts with flexible designs, ideal for consumer products and medical devices, but with lower strength than die-cast parts.

Die casting molds allow for the production of parts with tight tolerances and high-dimensional accuracy, making them ideal for applications where precision is crucial. This high level of precision is especially beneficial in industries like automotive and aerospace, where even small deviations can affect performance.

Die-cast parts often come with smooth surface finishes directly out of the mold, reducing the need for extensive post-processing. This feature not only improves the overall aesthetics of the component but also lowers production time and costs.

Die casting molds are well-suited for mass production of complex metal parts with intricate designs. The efficiency of the process, combined with the ability to integrate multiple features in a single part, makes it a go-to option for industries requiring high-volume production.

Die casting molds support material recycling, allowing manufacturers to reuse metal scrap generated during the casting process. This reduces material waste and lowers overall production costs, contributing to more sustainable and cost-effective manufacturing processes.

Injection molds can work with a variety of materials like plastics, rubber, and some metals, offering flexibility for different industries. This makes it ideal for producing diverse components, from consumer goods to medical devices.

Injection molding has a quicker production cycle, especially for plastic parts, reducing time-to-market. The molds also experience less wear compared to die casting molds, maintaining precision for longer runs.

Injection molding is cost-effective for producing parts with intricate designs and tight tolerances. It's particularly useful for high-precision components in industries like electronics and automotive.

Injection molding is great for low to medium-volume production. It’s an efficient option for smaller production runs, especially in industries like consumer goods where high-volume production is not required.

The material required for your parts plays a significant role in choosing between die casting and injection molding. Die casting is ideal for metal parts, especially aluminum, zinc, or magnesium alloys, which are commonly used in industries like automotive and aerospace. On the other hand, injection molding works best for plastics, elastomers, and some metals, making it more suitable for a wide variety of consumer goods, medical devices, and electronics.

If you need high-volume production, die casting is often the better option. It is highly efficient for mass-producing metal parts quickly and consistently, making it ideal for large-scale production runs. Injection molding, however, is more suitable for lower to medium-volume runs. While the tooling costs for injection molds may be lower, they shine when flexibility is needed for varying production volumes.

For parts with complex designs and tight tolerances, die casting molds are highly precise and can produce intricate features with excellent dimensional accuracy. However, if the part requires detailed textures, smooth finishes, or intricate geometries, injection molding offers a higher degree of design flexibility, especially for plastic components that may need complex internal features or hollow structures.

Tooling costs, production speed, and part durability are all critical in making a decision. Die casting molds generally have higher tooling costs but are well-suited for long-term use, particularly in high-volume production where the cost per unit becomes significantly lower. Injection molding has lower initial tooling costs, making it more cost-effective for smaller runs, but the overall per-part cost can rise in high volumes due to the need for faster cycle times and additional post-processing.

In conclusion, both die casting molds and injection molds have distinct strengths and limitations. Die casting molds are ideal for high-precision, complex metal components, making them suitable for industries such as automotive, aerospace, and industrial manufacturing. They offer excellent surface finishes and strength but come with higher tooling costs, making them more appropriate for high-volume production runs. On the other hand, injection molds provide versatility with a wide range of materials, including plastics and elastomers. They are well-suited for producing parts with intricate designs and tight tolerances, making them ideal for low to medium-volume production, especially in consumer goods and medical devices. The choice between die casting and injection molding ultimately depends on factors such as material requirements, production volume, design complexity, and budget. Each molding process has its own advantages, so understanding your product’s needs will help you make the best decision.