Views: 0 Author: Site Editor Publish Time: 2025-09-26 Origin: Site

In mold production, lead time is a critical factor that can significantly impact product development schedules and overall manufacturing efficiency. Long or unpredictable lead times often delay production, increase costs, and affect time-to-market for new products. Precision molds are essential for producing high-quality, accurate components, but their complexity can sometimes extend delivery timelines. By adopting in-house manufacturing for precision molds, companies can streamline the design-to-production process, reduce delays, and accelerate production cycles, ensuring faster turnaround without compromising quality or precision.

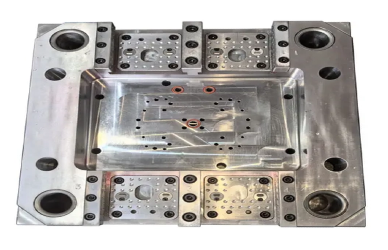

In-house precision mold manufacturing refers to the process of designing, producing, and finishing molds entirely within a company’s own facilities. This approach gives manufacturers full control over the entire mold lifecycle, from initial concept to final production, ensuring that every precision mold meets strict quality and performance standards.

In-house mold production encompasses all stages of mold development, including CAD/CAM design, CNC machining, mold flow analysis, surface finishing, and testing. By keeping these processes internal, manufacturers can closely monitor every step and maintain tight tolerances that are critical for high-precision applications.

Outsourcing mold production to third-party suppliers is a common practice, but it often introduces additional lead time, communication delays, and quality variability. With outsourced molds, design adjustments or revisions can take weeks due to shipping, coordination, and iterative feedback. In contrast, in-house production of precision molds allows immediate communication between design and production teams, enabling faster adjustments and reducing the risk of errors.

Quality Control: In-house facilities allow continuous monitoring of machining, surface treatment, and assembly, ensuring that each precision mold meets the required specifications.

Shorter Timelines: By eliminating reliance on external suppliers, in-house production accelerates the mold development process, from prototype to final mold, significantly reducing lead times.

Customization: In-house capabilities make it easier to implement design changes, optimize mold features, or produce specialized molds for complex parts, offering greater flexibility for unique production requirements.

In-house manufacturing offers significant advantages in reducing lead time for precision molds, enabling faster production without compromising quality.

With in-house capabilities, designers and engineers can work closely with production teams, creating immediate feedback loops. This allows potential design issues or process limitations to be identified and addressed quickly, ensuring that precision molds are optimized from the outset and minimizing delays caused by external communication.

Producing molds internally enables rapid prototyping and quick iteration of designs. If a precision mold requires modifications to improve fit, surface finish, or flow characteristics, adjustments can be implemented without waiting for third-party suppliers, significantly accelerating development cycles.

In-house production fosters seamless collaboration between engineers, designers, and manufacturing teams. This close coordination ensures that all aspects of the precision mold—from dimensional tolerances to surface treatment—are executed correctly the first time, reducing the risk of rework and miscommunication.

Outsourcing mold production often introduces additional time due to shipping, customs, or logistical challenges. In-house manufacturing eliminates these external dependencies, allowing precision molds to move directly from design to production, which shortens overall lead time and improves delivery reliability.

Beyond reducing lead time, in-house manufacturing offers several additional advantages for companies producing precision molds, enhancing overall efficiency and product quality.

By managing the entire mold production process internally, manufacturers can closely monitor machining, surface treatment, and assembly. This ensures that every precision mold meets strict dimensional tolerances and quality standards, minimizing defects and improving consistency across production batches.

In-house capabilities provide the flexibility to implement design changes or accommodate urgent orders quickly. If a precision mold requires adjustments due to prototype testing or client feedback, modifications can be executed immediately without waiting for external suppliers, ensuring that project timelines remain on track.

Producing precision molds in-house reduces dependence on third-party suppliers, eliminating additional costs associated with shipping, customs, and external coordination. It also mitigates the risk of delays caused by supplier scheduling or quality issues, providing more predictable project costs and timelines.

In-house mold production allows for seamless coordination with downstream manufacturing processes. Precision molds can be designed and adjusted to align perfectly with assembly lines, automated equipment, or production workflows, ensuring smooth integration and higher overall operational efficiency.

Shorter lead times in precision molds manufacturing provide strategic advantages across a wide range of industries, enabling faster product development and quicker market entry.

In the automotive and EV sectors, time-to-market is critical. High-precision components such as engine brackets, structural housings, and connectors require precision molds that meet tight tolerances and durability standards. In-house mold production allows rapid prototyping and faster iterations, ensuring that critical automotive parts are delivered on schedule without compromising quality.

Consumer electronics and industrial devices rely on housings and connectors produced with precision molds to ensure perfect fit, dimensional accuracy, and smooth surface finishes. Shorter lead times allow manufacturers to respond quickly to design changes, new product launches, or high-demand orders, maintaining flexibility and competitiveness in fast-moving markets.

For household appliances and other consumer goods, precision molds enable consistent quality, fine surface finishes, and reliable functionality. In-house mold production shortens the development cycle, allowing companies to meet seasonal or promotional demand more effectively and reduce inventory risks.

Industries with high-volume production, such as electronics, automotive, and small appliance manufacturing, benefit from precision molds produced in-house. Faster lead times allow for quicker scaling of production, reduced downtime, and the ability to respond rapidly to market trends, giving companies a competitive advantage in fast-paced industries.

Real-world examples demonstrate how in-house production of precision molds can significantly reduce lead time and improve manufacturing outcomes.

A leading automotive components manufacturer implemented in-house precision molds production for engine brackets and structural housings. By internalizing design, machining, and finishing processes, the company reduced the average mold lead time from 12 weeks to 5 weeks. This acceleration allowed faster prototyping, quicker design adjustments, and earlier production starts, helping the company meet tight product launch deadlines.

In another case, a consumer electronics manufacturer compared the performance of in-house versus outsourced precision molds for housings and connectors. The in-house molds achieved a 40% reduction in production cycle time and a 25% lower defect rate compared to outsourced molds. Faster iterations, direct communication between engineers and production teams, and tighter quality control contributed to more consistent dimensions, improved surface finish, and fewer rejected parts.

These examples illustrate the tangible benefits of in-house precision molds manufacturing, showing that companies can not only shorten lead time but also enhance quality, reduce defects, and increase overall operational efficiency.

In-house precision molds manufacturing plays a pivotal role in shortening lead times and improving overall production efficiency. By keeping the design, prototyping, and mold production processes internal, companies can respond quickly to design changes, accelerate product development, and maintain tighter quality control. This approach offers significant strategic value for industries that demand fast prototyping, rapid production, and high-volume output, such as automotive, electronics, and consumer products. To maximize these benefits, it is essential to partner with a manufacturer experienced in in-house precision molds production, ensuring optimal results in both quality and turnaround time.