Views: 0 Author: Site Editor Publish Time: 2025-09-19 Origin: Site

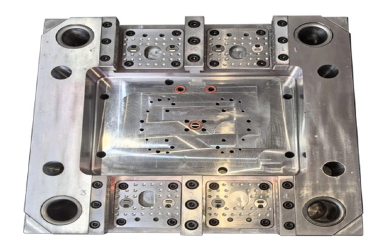

In die casting, molds play a critical role in shaping molten metal into high-precision components used across industries. They are essential for producing parts that require intricate designs, strength, and durability, such as engine blocks or electronic housings. The material selected for the mold directly affects its lifespan, performance, and the quality of the parts produced.

Choosing the right die casting mold material goes beyond durability. It’s about optimizing production efficiency, ensuring precision, and reducing costs. Whether aluminum, steel, or another alloy, each material has unique characteristics suited to specific production needs. By understanding these properties, manufacturers can better align their mold choices with product requirements, ensuring higher quality and more efficient processes.

Selecting the right material for die casting molds is key to achieving optimal performance, durability, and efficiency. Below is an overview of the most commonly used materials: steel, aluminum, and copper alloys, along with their benefits and drawbacks.

Steel is widely used for die casting molds due to its strength and durability.

Durable: Can withstand high pressures and temperatures, ideal for mass production.

Heat Resistant: Handles molten metals without damage.

Precision: Ensures high-quality, accurate parts.

High Initial Cost: More expensive to produce.

Longer Lead Time: Takes longer to manufacture due to material hardness.

Maintenance: Requires regular upkeep due to wear over time.

Aluminum molds are favored for lightweight and efficient casting, especially for low to medium-volume production.

Lightweight: Easier to handle and reduces equipment weight.

Good Thermal Conductivity: Faster cooling times improve production efficiency.

Cost-Effective for Low Volume: Ideal for smaller production runs.

Lower Durability: Wears out faster than steel, making it unsuitable for high-volume runs.

Limited Lifespan: May need to be replaced sooner due to softer material.

Copper alloys offer excellent thermal properties and durability, though they come at a higher cost.

Excellent Thermal Conductivity: Reduces cooling time for faster cycles.

Wear Resistant: Lasts longer than aluminum molds.

High-Quality Finish: Produces smooth, precise parts.

Higher Cost: More expensive than steel or aluminum.

Corrosion Risk: Requires maintenance to prevent degradation.

Limited Use: Less versatile for high-pressure applications.

Steel is the most commonly used material for die casting molds due to its strength, heat resistance, and longevity. Below, we explore the types of steel used, key advantages, and applications in high-volume production.

Characteristics: Hard, durable steel resistant to high pressure and heat.

Advantages: Offers excellent wear resistance, toughness, and maintains hardness at high temperatures.

Characteristics: Designed to withstand extreme thermal cycles.

Advantages: High thermal conductivity and excellent resistance to thermal fatigue.

Steel molds are highly resistant to deformation, ensuring a long lifespan and making them ideal for high-volume production.

Steel molds can endure the high temperatures required for casting materials like aluminum and magnesium, maintaining structural integrity despite frequent thermal cycles.

Steel molds provide excellent dimensional accuracy and surface finishes, ensuring consistent quality across production runs.

Steel molds are used for manufacturing parts such as engine blocks and transmission housings, which require strength and heat resistance.

Steel molds are ideal for producing high-precision parts like turbine blades and structural elements that must withstand extreme conditions.

Steel molds are used in producing durable, high-performance parts such as pump housings and motor components.

Aluminum molds are gaining popularity in die casting, especially in industries that require faster production cycles and cost-effective solutions. Here's an overview of aluminum's role in die casting mold production, along with its advantages and suitable applications.

Aluminum is widely used in die casting molds for its ability to be easily machined and its favorable balance of properties, such as lightweight and cost efficiency. It is often selected when the production volume is moderate, or the complexity of the design is relatively simple.

Aluminum molds are significantly lighter compared to steel molds. This makes handling and maintenance easier and faster, especially for smaller production runs.

Aluminum is more affordable than steel, reducing initial material costs. This makes it a popular choice for industries looking to cut costs without sacrificing performance for certain applications.

Aluminum molds are easier and faster to machine than steel molds. This results in shorter lead times for prototype development and small-scale production runs, which is ideal for companies requiring quick turnaround times.

Aluminum molds are an excellent choice for small to medium production runs where cost efficiency and quicker production cycles are essential, and the overall volume doesn’t justify the use of more expensive, high-durability steel molds.

If the part design isn’t highly intricate or demanding in terms of heat resistance, aluminum molds can provide sufficient precision and performance at a lower cost.

Copper alloys, such as bronze and brass, offer distinct advantages in die casting molds due to their excellent heat conductivity and strength. These materials are particularly useful in high-temperature environments and demanding production processes.

Copper alloys dissipate heat rapidly, preventing mold overheating and ensuring consistent casting quality, especially in high-volume production.

Copper alloys are highly resistant to wear and fatigue, making them ideal for repeated heating and cooling cycles, preserving mold integrity over time.

Copper alloys provide a smooth surface, contributing to high-quality finishes on die-cast parts, especially for industries requiring aesthetic precision.

Perfect for parts exposed to extreme heat, such as automotive engine blocks or aerospace components, where thermal stability is essential.

Due to their thermal cycling durability, copper alloys are ideal for high-volume production requiring consistent precision.

Commonly used in powertrain parts or heat exchangers, where heat resistance is critical to performance and longevity.

Apart from common materials like steel, aluminum, and copper alloys, several specialized materials are used in die casting molds to meet specific performance needs such as wear resistance, corrosion resistance, and thermal stability. These materials are essential in industries like automotive, aerospace, and electronics.

Beryllium copper is known for its strength, thermal conductivity, and electrical properties.

Thermal Conductivity: Ideal for molds requiring efficient heat dissipation, like automotive parts.

Strength: Provides high strength, perfect for high-pressure casting.

Corrosion Resistance: Highly resistant to corrosion, particularly in harsh environments.

Heat-sensitive Components: Used for parts like electrical connectors or heat exchangers that need precise temperature control.

Bronze, an alloy of copper and tin, is favored for its durability and wear resistance.

Wear Resistance: Offers excellent hardness, ideal for molds exposed to abrasive conditions.

Corrosion Resistance: Performs well in wet or corrosive environments.

Longevity: Ideal for long production cycles without degradation.

High-Wear Parts: Used in molds producing engine components or industrial machinery parts.

Carbide, made from tungsten or silicon carbide, is known for its hardness and wear resistance.

Extreme Hardness: Withstands high wear, making it suitable for high-precision applications.

Thermal Stability: Performs well under high temperatures.

Low Friction: Helps reduce part sticking and mold erosion.

High-Precision Parts: Used in molds for medical devices, aerospace components, or parts with tight tolerances.

Choosing the right material for a die casting mold is crucial for achieving optimal performance, quality, and efficiency in production. Key factors to consider include part complexity, production volume, cost, and mold performance.

For intricate designs, stronger materials like steel or beryllium copper are ideal for maintaining precision. Simpler parts can be made with cost-effective materials like aluminum or zinc.

High-volume production demands durable materials that can withstand repeated use, such as steel. For lower-volume runs, aluminum molds are more affordable and suitable for quicker turnaround.

Aluminum and zinc alloys are cheaper, making them ideal for smaller runs. Steel molds, while more costly, offer better durability for long-term, high-volume production.

Materials like steel and copper alloys provide better heat resistance, wear resistance, and longevity. For high-temperature or high-wear applications, these materials are more durable, reducing maintenance costs.

Molds made from steel or carbide offer superior precision and consistency, reducing defects. For general applications, aluminum and zinc alloys offer sufficient quality at a lower cost.

Selecting the right material for die casting molds is crucial for ensuring performance, precision, and cost-effectiveness. Whether it's steel for durability, aluminum for cost-efficiency, or copper alloys for heat resistance, the right material influences part quality, mold lifespan, and production efficiency. Key factors like part complexity, production volume, and cost should guide the material choice.

Advancements in materials technology are shaping the future of die casting. New materials and coatings are enhancing mold performance, wear resistance, and sustainability. These innovations will enable the production of more complex, lightweight, and efficient parts, particularly in sectors like automotive and aerospace, driving ongoing progress in manufacturing.