Views: 0 Author: Site Editor Publish Time: 2025-09-22 Origin: Site

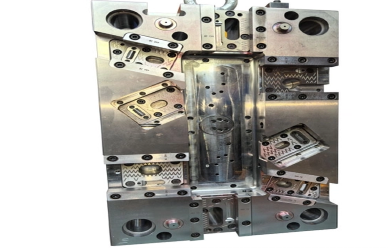

In modern manufacturing, precision molds are central to achieving high-quality die-cast parts. Die casting is widely used in automotive, electronics, and household industries because it enables mass production of complex components with good dimensional stability and surface finish.

Aluminum die casting is valued for its lightweight strength, often used in structural parts and housings. Zinc die casting offers superior accuracy and durability, making it ideal for locks, key fobs, brackets, and decorative components.

This leads to a key question: why are precision molds the foundation of die casting accuracy? The answer lies in their ability to control tolerances, minimize defects, and ensure consistent results in high-volume production.

Achieving consistent accuracy in die casting is not easy. Even with advanced machines and skilled operators, the performance of precision molds is directly affected by several challenges. These can be grouped into three main areas: material properties, process control, and common defects.

Aluminum alloys are highly valued for being lightweight and strong, which is essential in industries such as automotive and electronics. However, they are prone to higher shrinkage during cooling and carry a greater risk of porosity, making dimensional accuracy harder to maintain.

Zinc alloys provide excellent precision and surface finish, which is why they are widely used for locks, brackets, and decorative parts. Yet, zinc can deform under stress, requiring precision molds to carefully manage part geometry and stability.

Uneven wall thickness in complex parts creates difficulties in achieving full and uniform filling. If the mold design is not precise, it may lead to incomplete structures or stress points.

Temperature and injection pressure control is another critical factor. Any fluctuation in molten metal flow or cooling rate can compromise dimensional accuracy, which is why precision molds must be designed with optimized gating and cooling systems.

Despite careful planning, defects are common in die casting. Porosity, shrinkage, and warpage often occur when mold precision or process control falls short. Dimensional deviations, even on a small scale, can make parts unusable for industries like automotive, where tolerances are extremely tight. This is why precision molds are indispensable in minimizing such risks and ensuring consistent quality.

Precision molds play a crucial role in enhancing the accuracy of aluminum and zinc die-cast parts. Their impact spans the design, manufacturing, and process control stages, ensuring that each component meets tight tolerances and high-quality standards.

Mold flow analysis: One of the key functions of precision molds is to incorporate mold flow simulations during the design phase. This allows engineers to optimize gating, runners, and vents, ensuring uniform metal flow and reducing the risk of defects such as porosity or incomplete filling.

Compensation for alloy shrinkage: Different alloys shrink at different rates during cooling. Precision molds are designed with built-in compensation to counteract these variations, helping maintain dimensional accuracy across both aluminum and zinc castings.

CNC machining: Achieving a tolerance of ±0.01mm requires high-precision CNC machining. Precision molds ensure that the mold cavities are exactly as designed, which directly translates to accurate and consistent part production.

Surface treatments: Polishing, chrome plating, and PVD coatings are commonly applied to precision molds to create smooth cavity surfaces. These treatments not only improve part surface finish but also reduce friction during ejection, minimizing defects like drag marks or scratches.

Optimized cooling channels: Temperature consistency is vital in die casting. Precision molds are equipped with well-designed cooling channels that maintain uniform temperature throughout the mold, reducing internal stresses and shrinkage variations.

Heat treatment: Precision molds undergo specialized heat treatment to enhance durability and maintain dimensional stability over long production cycles. This ensures that molds consistently produce high-quality parts even after thousands of cycles.

Precision molds are essential for achieving high-quality aluminum die-cast components, especially in applications where strength, lightweight design, and dimensional accuracy are critical.

Aluminum die casting is widely used in automotive structural parts, such as brackets, housings, and engine components, where weight reduction is essential without compromising strength. It is also used in heat sink housings for electronics, which require precise dimensions and excellent thermal performance. In all these applications, the use of precision molds ensures consistent quality and repeatable results.

Porosity is a common challenge in aluminum die casting due to high shrinkage and air entrapment. Precision molds help minimize this issue by enabling optimized gating and runner designs. Additionally, precise cooling channel layouts maintain uniform temperature throughout the mold, reducing internal stress and ensuring that molten aluminum fills the cavity completely without forming voids.

Thin-wall components, such as housings with wall thicknesses ≤0.8mm, present significant challenges in aluminum die casting. Using precision molds, manufacturers can achieve stable and consistent casting of these ultra-thin parts. High-precision cavity design, combined with controlled cooling and injection parameters, ensures dimensional accuracy while preventing defects like warpage or incomplete filling.

Precision molds play a critical role in producing high-quality zinc die-cast components, particularly for parts where surface finish and dimensional accuracy are essential.

Zinc die casting is commonly used in automotive key fobs, lock housings, and electronic enclosures. These components often have complex shapes, fine details, and tight tolerances, making precision molds indispensable for consistent and accurate production.

Many zinc die-cast parts are visible to end users, such as key fobs and decorative housings, where surface aesthetics are crucial. Precision molds, combined with proper cavity polishing and surface treatment, help achieve smooth finishes and prevent defects like scratches, drag marks, or uneven surfaces, ensuring that the final product meets both functional and visual standards.

In high-volume production, precision molds can be designed as multi-cavity molds, enabling several parts to be produced in a single cycle. This not only increases production efficiency but also ensures uniform quality across all parts. Consistent dimensional accuracy and surface finish are maintained even in large-scale manufacturing, which is essential for industries like automotive and electronics.

Precision molds provide clear advantages for both manufacturers and clients, especially in high-precision die casting.

By ensuring accurate cavity dimensions and optimized mold flow, precision molds reduce defects like porosity, warpage, and dimensional deviations, lowering scrap and rework.

Precision molds deliver high repeatability, ensuring parts meet tight tolerances and are fully interchangeable—critical for automotive and electronic components.

Although the initial investment may be higher, precision molds lower overall costs by minimizing defects, rework, and downtime.

Precision molds help meet IATF 16949 and ISO 9001 standards, ensuring reliable, high-quality parts for automotive applications.

Precision molds are the cornerstone of achieving accuracy in both aluminum and zinc die casting, ensuring consistent dimensions, high surface quality, and reliable performance. They provide significant value to industries such as automotive, electric vehicles, electronics, and household appliances, where quality and precision are critical. Partnering with an experienced precision mold manufacturer is essential to secure high-quality production outcomes, reduce defects, and maintain efficiency across large-scale manufacturing.