Views: 0 Author: Site Editor Publish Time: 2026-01-26 Origin: Site

Zinc alloy is the best material for high-precision electronic parts. Zinc die casting makes parts that are very accurate in size. The parts also have a smooth surface. This process gives you the same results every time.

Zinc alloy parts are 17.8% stronger than ACuZinc5 alloy parts.

You get many good things from zinc. It has strong mechanical strength. It lasts a long time. It does not attract magnets. It does not rust easily. Zinc also saves money on your project. If you want parts you can trust, use zinc alloy for your next electronic design.

Zinc alloy gives very exact and accurate parts for electronics, so pieces fit just right.

Zinc die casting makes parts that are always the same, so you can make many good parts again and again.

Zinc alloys do not rust or wear out easily, so they are great for things used outside or in electronics that need to last a long time.

Using zinc alloy can save money when making things because it melts at a lower temperature and is easy to shape.

Zinc does not attract magnets, so it helps keep important electronics safe from electromagnetic problems.

You want your electronic parts to fit just right. Zinc die casting helps you do this. The process uses zinc alloy that flows well. It fills the mold and shows every detail. You get parts with tight tolerances and smooth surfaces. Zinc die casting makes high-precision parts that meet strict rules.

Tip: Dimensional accuracy means your parts are the exact size and shape you need. This is very important for electronic components that must fit together without mistakes.

The table below shows the usual tolerances you can get with zinc die casting:

Tolerance Type | Value |

|---|---|

Routine Tolerances | ±0.001 in/in (±0.025 mm/25 mm) |

Standard Tolerances | ±0.127 mm (±0.005") |

Achievable Precision Tolerances | ±0.025 mm (±0.001") |

These numbers show zinc die casting gives some of the best tolerances. You can trust this process for small and complex parts.

Zinc casting alloys flow very well. The melted zinc moves into every part of the mold. You get sharp corners, thin walls, and fine details. Many electronic devices need these features to work right. When you pick zinc die casting, your components will fit and work as planned.

You want every part to be just like the last one. Zinc die casting gives you this. The process uses exact molds and careful steps. Each cycle repeats the same actions. This means you get steady quality and the same results every time.

Let’s look at how zinc die casting compares to other materials:

Material | Fluidity and Tolerances | Strength and Stability | Corrosion Resistance | Cost |

|---|---|---|---|---|

Zinc | Excellent, maintains tight tolerances | Strong and stable | High | Lower cost |

Aluminum | Good, versatile | High strength-to-weight ratio | Excellent | Higher than zinc |

Magnesium | Moderate, less stable under stress | Good strength-to-weight ratio | Good | Higher than aluminum |

Zinc is great because it flows well and holds tight tolerances. You get strong, steady parts for less money. This makes zinc casting alloys a smart pick for electronic components.

Quality is not just about the material. It is also about the process. Makers use quality systems like ISO 9001 and IATF 16949. These rules help you get the same quality in every batch. Here are some steps used to keep quality high:

Phase of Production | Quality Control Activities |

|---|---|

Design Phase | Quality team checks if the product can be made and looks at what the customer wants. |

Production Phase | Quality controls follow control sheets, with regular sampling and testing. |

Control Process | Importance |

|---|---|

Control Sheets | Help guide quality checks during production. |

Testing | Makes sure the parts meet customer needs with regular checks. |

Every step in zinc die casting is important. Mold making, melting, injection, cooling, ejection, and finishing all matter. Careful control at each stage helps you get the parts you need. After casting, more steps turn raw castings into good components. This is important for electronic parts that must work every time.

Note: Industry standards like NADCA help everyone know what quality means for zinc die casting. You and your maker can use these rules to make sure your parts are what you want.

Zinc die casting gives you the accuracy, precision, and quality you need for electronics. You can count on this process for high-precision parts that last.

Electronic parts need to be strong and last long. Zinc casting alloys are a good choice for this. They mix strength, hardness, and toughness well. These alloys can handle about 54,000 psi of force. This means your parts will not break or bend easily. ZAMAK 3, ZAMAK 5, and ZA-8 are common zinc casting alloys. Each one has special features for different uses.

Zinc alloys flow well, so they fill molds and make strong parts.

Zn-Ni coatings make zinc parts even tougher. On the Vickers hardness scale, Zn-Ni coated parts score 450. This is much higher than normal zinc coatings.

In SAE J2334 Cyclic Corrosion tests, Zn-Ni coatings last four times longer than regular zinc coatings.

Car makers use zinc casting alloys for gears and engine parts. These parts must handle a lot of stress and movement. Gears made from Zamak 5 are strong and resist wear. You can count on these alloys for tough jobs.

You want your electronic parts to last a long time. Zinc casting alloys help you reach this goal. These alloys resist hits and wear better than many other materials. Builders use zinc alloys for outdoor fixtures in rough places. They last up to 30% longer than old materials.

Zinc casting alloys stay strong even after many uses.

Brackets and fittings made from zinc work well in tough electronic places.

Car and electronics makers use zinc for parts that need to fit well and be high quality.

Zinc casting alloys are also easy to shape and finish. You can make your parts just how you want them. The high-fluidity zinc alloy fills every part of the mold. This gives your parts the right size and quality. Checking each part during casting makes sure they meet your needs.

Tip: Pick zinc casting alloys when you need parts that fit well, are high quality, and last a long time.

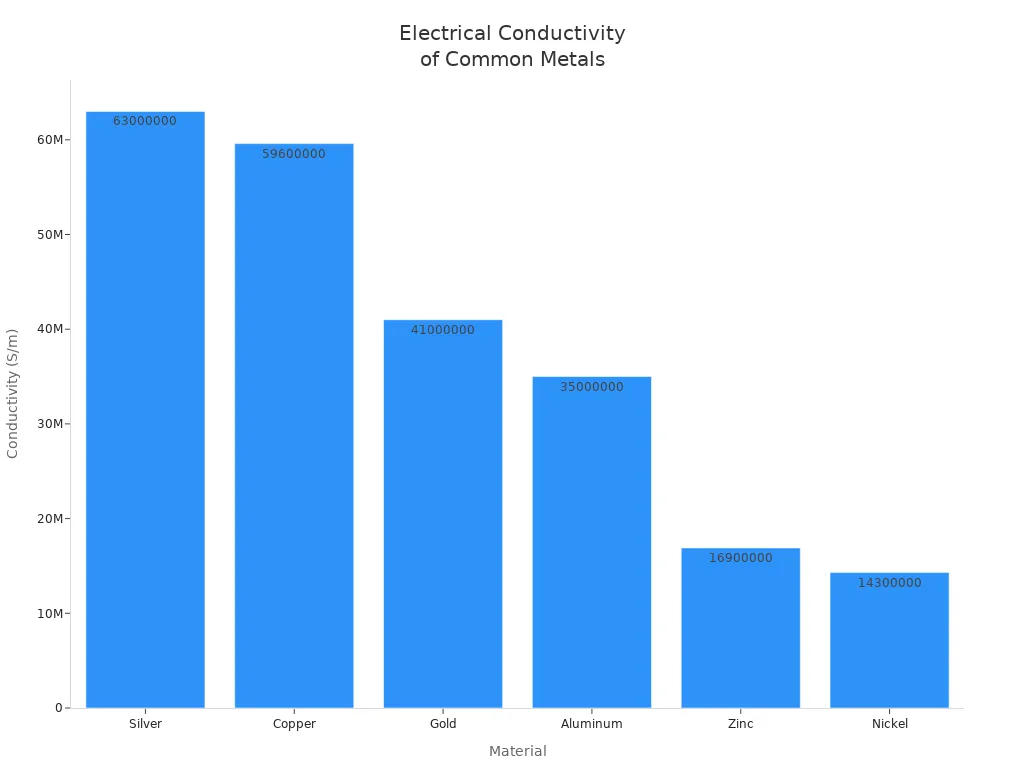

You want your electronic parts to work every time. Zinc alloy lets electricity flow well in your parts. It is not as good as copper or silver, but it still works for many uses. Zinc’s atomic structure and how it mixes with other metals help it carry electricity. Look at the table below to see how zinc compares to other metals:

Material | Conductivity (S/m) |

|---|---|

Silver | 6.30×10^7 |

Copper | 5.96×10^7 |

Gold | 4.10×10^7 |

Aluminum | 3.5×10^7 |

Zinc | 1.69×10^7 |

Nickel | 1.43×10^7 |

Zinc alloy parts are also good for circuits. They are easy to solder. They do not lose contact easily. They last a long time because they resist wear. Sn-Zn coatings protect steel and help circuits work better. Ductile zinc alloy parts can bend without breaking. This means you can use them in many ways.

Tip: If you pick zinc alloy, your circuits will work well and last longer.

You do not want magnets to mess up your electronics. Zinc alloy is non-magnetic, so it does not attract magnets. It does not cause problems with magnetic fields. This is important for things like medical devices and other sensitive electronics. Non-magnetic zinc alloy parts keep your circuits safe from extra signals.

Zinc alloy helps block electromagnetic interference. Your assemblies get better electromagnetic compatibility. Here are some good things about zinc alloy:

Zinc alloy blocks EMI from reaching your parts.

You get strong, flexible, and tough designs for electronics.

Non-magnetic zinc alloy parts keep circuits steady and high quality.

Note: Zinc alloy helps stop magnetic problems and keeps your parts working well.

You can trust zinc alloy for high-precision electronic parts. It gives you steady electrical performance and protects against magnetic trouble.

You want your electronic parts to last a long time. Zinc alloy helps protect them from rust and damage. It acts like a shield against water, air, and chemicals. Zinc-manganese alloys make a special layer called manganese oxide. This layer stops corrosion, even in places with seawater or pollution. You can add extra treatments to make the protection stronger. These steps help your parts stay tough and keep working well.

Zinc-manganese alloys create a strong oxide layer.

The layer blocks rust and keeps parts safe.

Extra treatments make the shield even better.

Your components stay safe in rough places.

Tip: Use zinc alloy for outdoor or factory electronics. It helps your parts last longer and saves you money on repairs.

You want to spend less and still get good parts. Zinc alloy helps you do this. It melts at a lower temperature than aluminum. This means you use less energy to make parts. Zinc die-casting molds last a long time, sometimes up to a million uses. You do not need to buy new molds often, so you save money. Zinc alloy also lets you use less metal for each part, which saves time and money.

Zinc needs less heat to melt and cast.

Zinc molds last longer than aluminum molds.

You use less metal for each part.

Zinc alloy parts are easy to finish and plate.

Zinc alloy gives you strong and bendable parts. Your components stay tough, even after lots of use. The table below shows why zinc alloy is a smart choice for saving money:

Factor | Description |

|---|---|

Cost-effectiveness | Zinc is common and costs less than other metals, so it is good for making lots of parts. |

Excellent castability | Zinc melts easily and flows well, so you can make detailed parts with few mistakes. |

High strength and durability | Mixing other metals with zinc makes parts strong and long-lasting. |

Corrosion resistance | Zinc alloys do not rust easily, so they work well in tough places. |

Versatility | You can use zinc alloy for car parts, electronics, home goods, and decorations. |

Note: If you pick zinc alloy, you get strong parts, good quality, and lower costs for your electronics.

Zinc can be shaped into many different designs. It moves into molds without trouble. You get parts with sharp corners and thin walls. The details are very clear. Zinc alloy makes parts that other metals cannot make. You can cast pieces as thin as 0.025 inches. This makes the parts lighter and uses less material. The surface is smooth, so you do not need much extra work. Zinc gives you close tolerances. This means your parts fit together just right.

Tip: Zinc helps stop mistakes in your parts. The molds last longer, so you get better quality and save money.

Check out the table below to see what zinc can do for your designs:

Feature | Description |

|---|---|

High Fluidity | Zinc fills tricky mold spaces for detailed designs. |

Thin-Walled Components | You can make parts as thin as 0.025 inches. |

Excellent Finishability | Zinc gives a smooth surface, so you need less finishing. |

Dimensional Accuracy | You can get tolerances as tight as 0.025 mm. |

Ductility and Impact Resistance | Parts can handle stress and last longer. |

Zinc alloy is used in many electronic parts. These include connectors, housings, heat sinks, and brackets. Zinc makes strong bases and mounting plates. You also see it in bezels and trim pieces. These look nice and last a long time.

Electronics get smaller every year. Zinc helps make this possible. You can make tiny parts with complex shapes and small details. Zinc lets you make lots of parts fast. This helps companies keep up with what people want. Zinc also blocks outside signals, so your devices stay safe.

Electronics use more zinc because small parts need good heat control.

Zinc’s flexibility lets you make tricky shapes and fine details for small devices.

Making things smaller helps the zinc die-casting business grow.

Zinc alloy is the best pick for small, strong, and exact parts. You get tools that last longer and better quality. Zinc makes your designs work, even when other materials cannot.

You want your electronic parts to last a long time and work well. Zinc alloy makes parts that are very exact and strong. The surface of zinc parts is smooth and looks good. Zinc helps protect your parts from signals that can cause problems. It also stops sparks and flows into molds easily. Many companies use zinc because it makes parts you can trust. If you pick zinc, you spend less money and get tough parts for your designs.

Strength, hardness, and rigidity

Excellent surface quality

Shielding against electromagnetic interference

Anti-sparkling property

Fluidity

You should think about using zinc for your next project. Ask experts for help if you need special parts.

You get tighter tolerances with zinc alloy. Zinc flows into molds more easily. You can make smaller, more detailed parts. Zinc also costs less to cast and finish.

Yes, you can. Zinc alloy resists rust and corrosion. You can add coatings for extra protection. Your outdoor devices will last longer with zinc alloy parts.

You do not need to worry. Zinc alloy does not attract magnets. It blocks electromagnetic interference. Your circuits stay safe and work as planned.

Zinc alloy lets you make thin, complex shapes. You can design very small parts with fine details. This helps you build modern, compact electronics.