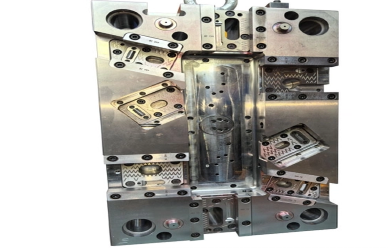

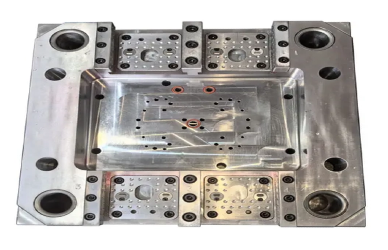

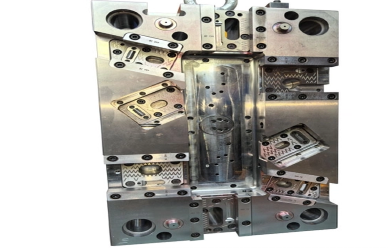

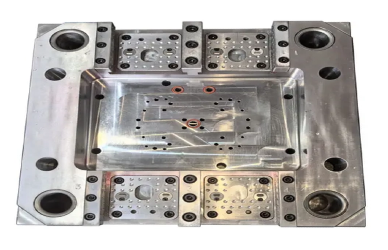

2025-09-25 Precision molds are essential in modern manufacturing and die casting, providing high accuracy, consistent dimensions, and superior surface finishes for critical components. To ensure long-term performance, durability, and high-quality output, the surface of these molds must be properly treated. Surface treatments enhance mold life, improve part release, and reduce defects, while also ensuring the finished parts meet aesthetic and functional requirements.

Read More

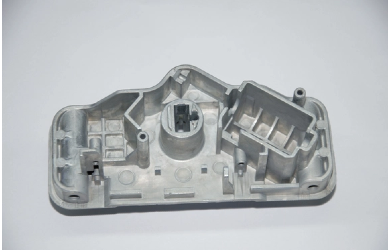

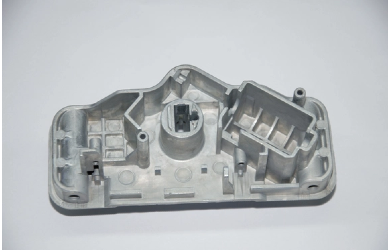

2025-09-22 Molding processes are essential in modern manufacturing for producing precise, high-quality parts. Die casting molds are used to shape molten metals like aluminum and zinc into durable components, while injection molds typically shape plastics, rubber, and metals by injecting molten material into a mold cavity under pressure.

Read More

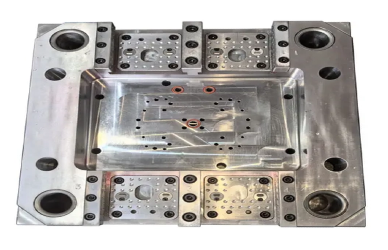

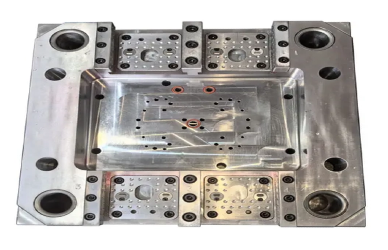

2025-09-22 Molds are a fundamental component in manufacturing and die casting, determining the shape, accuracy, and surface quality of finished parts. Choosing the right mold is critical, as it directly affects production efficiency, overall cost, and the final product’s performance. Among the available options, precision molds stand out for their ability to achieve tight tolerances and high-quality finishes, while standard molds are often sufficient for simpler, non-critical components.

Read More

2025-09-22 In modern manufacturing, precision molds are central to achieving high-quality die-cast parts. Die casting is widely used in automotive, electronics, and household industries because it enables mass production of complex components with good dimensional stability and surface finish.

Read More