Views: 0 Author: Site Editor Publish Time: 2025-09-19 Origin: Site

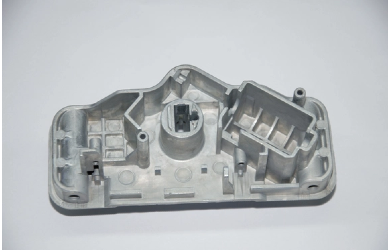

Die casting is a widely used manufacturing process that involves injecting molten metal into a precisely designed mold under high pressure. It is particularly important in high-volume production, where efficiency, speed, and consistent quality are crucial. Die casting molds are at the heart of this process, shaping the molten metal into high-precision components for industries ranging from automotive to electronics.

These molds are essential for producing parts that require intricate designs, high strength, and dimensional accuracy. By enabling rapid production cycles and minimizing material waste, die casting molds ensure that large quantities of parts are produced with consistent quality and minimal defects. The choice of mold material and design plays a critical role in optimizing production efficiency, ensuring that parts meet stringent performance standards while keeping costs down. Whether it's for mass-market products or high-performance components, die casting molds are key to maintaining the balance between production speed, cost-effectiveness, and quality.

Die casting is known for its fast cycle times, typically ranging from 15 seconds to a few minutes depending on part complexity. This speed is achieved through the quick solidification of molten metal, aided by high-pressure injection that rapidly fills the mold cavity. The result is fast, efficient production with minimal delays.

Die casting molds, made from durable materials like steel or aluminum, are engineered to withstand high-pressure injection and allow for quick part ejection. With features like cooling channels and ejector systems, molds support rapid cycle times, making them ideal for mass production. Once cooled, the mold opens, ejects the part, and is ready for the next cycle.

Die casting molds enable manufacturers to meet large-scale demands by producing thousands of parts quickly and consistently. This efficiency is critical in industries like automotive, where fast production is essential. The high-speed process helps reduce costs, minimize downtime, and accelerate time-to-market, giving manufacturers a competitive edge in meeting customer demands.

Die casting molds are engineered to produce components with exceptional accuracy and tight tolerances. The high-pressure injection process ensures uniform filling of the mold, resulting in parts with precise dimensions. This makes them ideal for industries like automotive and aerospace, where precision is critical.

A major advantage of die casting molds is their ability to maintain consistent quality across large volumes. Once a mold is tested and approved, it can be used repeatedly, ensuring that each part meets the same specifications. This consistency is essential for applications that require parts to fit and perform reliably in assemblies.

In high-volume production, tight tolerances and minimal defects are crucial. Die casting molds are designed to produce parts that require little to no additional machining, reducing costs and the risk of defects. This leads to higher product reliability and fewer scrap rates, enhancing production efficiency and overall cost-effectiveness.

Die casting molds are designed to use precise amounts of molten metal, ensuring minimal excess and reducing waste. This precision allows manufacturers to achieve complex part designs while optimizing material usage, making the process more efficient.

Die casting molds help minimize scrap metal by maintaining tight tolerances and precise cavity designs. This results in fewer defects and reduces the need for secondary operations, leading to lower material waste and costs. The process is inherently efficient, contributing to a more sustainable production cycle.

Scrap metal, such as runners and gates, can be easily recycled in die casting. By melting and reusing this excess material, manufacturers reduce material costs and minimize waste, supporting both sustainability and eco-friendly practices in production.

Die casting molds allow for the production of complex components that are difficult to achieve with traditional methods. The high-pressure injection process fills intricate mold cavities, producing parts with thin walls, intricate shapes, and integrated features like ribs and cooling channels. This reduces the need for secondary operations, improving production efficiency.

In industries like automotive and aerospace, lightweight components are crucial for improving fuel efficiency and performance. Die casting molds enable the use of lightweight materials such as aluminum and magnesium alloys, which offer strength and reduced weight. This capability allows manufacturers to design parts that are both durable and lightweight, meeting the high-performance standards of these industries.

Die casting molds are used to create high-performance components like engine blocks, transmission housings, and structural parts in automotive applications. These parts provide the required strength while reducing weight, enhancing fuel efficiency. Similarly, in aerospace, die casting is used to make components like turbine housings and brackets, where intricate designs and weight reduction are essential.

Die casting molds are made from high-strength materials like tool steel or hot work steel, designed to endure the pressures and temperatures of molten metal injection. These molds are engineered for repeated use, resisting wear and deformation, making them perfect for high-volume production.

Molds are exposed to extreme heat and pressure during the die casting process. To maintain their integrity, die casting molds include features like heat-resistant coatings and reinforced cores, ensuring they withstand thousands of cycles without degradation.

Quality die casting molds, with proper care, can last for extended cycles, reducing the need for frequent replacements and repairs. This leads to lower maintenance costs, minimal downtime, and more efficient manufacturing, particularly in industries like automotive and electronics.

Die casting molds allow the creation of complex parts with multiple functions in a single component, eliminating the need for several individual parts. This integration simplifies the production process and enhances the overall functionality of the product.

By combining features into one part, die casting molds streamline product designs, reducing the number of components and minimizing potential failure points. This leads to a more efficient manufacturing process and lower assembly costs.

In the automotive industry, die casting molds create engine blocks with integrated cooling channels, reducing the need for separate cooling components. In electronics, die-cast housings may combine mounting points, heat dissipation, and electrical pathways. These multifunctional designs improve product performance and reduce manufacturing time.

Die casting molds are essential in high-volume manufacturing, offering significant benefits in efficiency, precision, and cost-effectiveness. They enable rapid production cycles, allowing for consistent, high-quality components without compromising on performance. With tight tolerances and precision, die casting molds meet the demanding standards of industries like automotive and aerospace.

These molds also optimize material usage, reduce waste, and offer long-lasting durability, resulting in fewer replacements and lower maintenance costs. Additionally, they support the creation of complex, lightweight designs, enhancing product functionality.

In summary, die casting molds help manufacturers achieve fast, cost-efficient, and high-quality production, driving innovation in mass manufacturing and ensuring competitive advantages in industries requiring precision-engineered components.